Dealcoholization

Advantages of Memo3 membrane technology for dealcoholization

Gentle batch process

Without thermal load

Low pressure

The process - dealcoholization with membrane technology

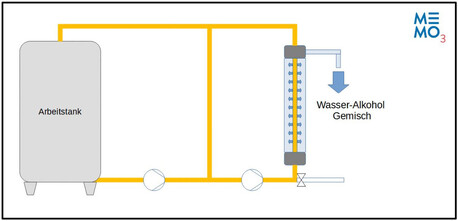

In dealcoholization using membrane filtration, the membrane is designed in such a way that alcohol and water can pass through the membrane, while the aromas and other ingredients of the beer remain in the cycle. This dealcoholization process takes place in several steps:

Concentration

Dealcoholization is carried out in a batch process using normal, alcoholic beer as the starting product. This is continuously pumped through the filter module, which is located in a working tank. During the filtration process, water and alcohol can pass through the membrane, while the other ingredients are retained and remain in the circuit. Over time, this process leads to the formation of a beer concentrate.

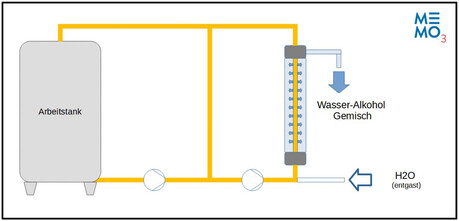

Diafiltration

In the second step, the amount of water-alcohol that was removed during filtration is replaced by the same amount of degassed water. This process leads to a continuous reduction in the alcohol content. In a fully automated system, the point at which the specified alcohol content is reached can be determined automatically by measuring the alcohol content inline. The process continues until the desired alcohol concentration is reached.

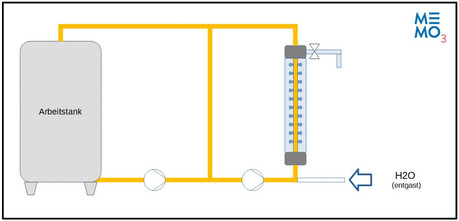

Redilution

In the final step of the process, the dealcoholized beer concentrate is rediluted with deaerated water. This step leads to the production of the finished product, be it alcohol-free or alcohol-reduced, which can be bottled after carbonation. This process ensures the consistency and quality of the final product so that it meets consumer expectations and the highest standards in the brewing industry.

Produkte

MALS 500 / 1000 / 2000

With its innovative, compact, membrane-based technology, Memo3 offers you the opportunity to make better use of your own capacities. With low process temperatures and maximum protection for your valuable product, you can produce your own products with any desired residual alcohol content from any base beer.

With our compact "MALS" membrane system, you have the option of reducing the alcohol content of your beverages (e.g. beer, wine, cider) to the "alcohol-free" level. In order to preserve the typical taste of your valuable product, we use a particularly gentle process (hygienic - oxygen-free - low temperature).

Regardless of whether you want to dealcoholize small or large batches of different varieties - with our MALS membrane system you are flexible and independent. With this solution, you can delight your customers with high-quality non-alcoholic beverages and expand your product portfolio to meet increasing market demands. Types of MALS system (500, 1000, 2000)

MALS TP

Thinking big can also be small - discover a new dimension of dealcoholization with the MALS TP.

Compact and powerful, it enables you to reduce the alcohol content of your beverages precisely according to your requirements. Our gentle process at low temperatures preserves the unique taste of your high-quality product.

The MALS TP is the answer to the challenges of the modern beverage industry. Thanks to its compact size, it is unrivaled in terms of mobility and offers flexible set-up for testing or directly at the point of sale.

Find out more about the compact MALS TP at an attractive fixed price and enter the future of dealcoholization with Memo3.

Nano Flavor® for dealcoholization of beer

In a successful cooperation, Memo3 and banke GmbH have developed an innovative plant concept for dealcoholization. Our extensive expertise in membrane technology and banke GmbH's many years of experience in process technology for breweries have complemented each other perfectly in this partnership.

The result of this cooperation is a compact hollow fibre membrane-based system for dealcoholization. The modular design allows different plant sizes and offers various automation options. This flexible solution enables our customers to optimally meet their individual requirements and implement efficient dealcoholization processes in their breweries.

Your advantages - The innovative hollow fiber filtration module enables a gentle process at low pressure and low temperature.

- You benefit from a high degree of flexibility; the systems are available in various sizes and automation levels to suit the needs of your business.

- Achieve independence and creative freedom by carrying out your own dealcoholization on site.

Pilot plant for your non-alcoholic beer

Are you ready to break new ground? We offer you the opportunity to explore and thoroughly test our dealcoholization process using membrane filtration. This gives you the chance to experience the taste of your non-alcoholic beer based on your own products at first hand.

Our dealcoholization pilot plant is the ideal platform for refining your beer and carefully testing the dealcoholization process in your brewery.

Our system is equipped with two separate membrane modules, a winding module and a capillary module. These differ in their design, performance and operating pressure. During the test phase, you can determine which option best suits your operation.

The system is usually available to you for a test period of four weeks so that you can dealcoholize and taste various products. Of course, you will receive comprehensive instruction from our process expert.

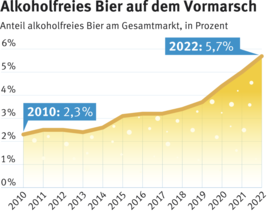

Use case: Non-alcoholic beer

The market for non-alcoholic beverages, especially non-alcoholic beer, is experiencing sustained growth worldwide, including in Germany, Austria and Switzerland.

Take advantage of this growth opportunity and rely on our innovative and gentle dealcoholization solution, which is based on state-of-the-art membrane technology. Our membrane solution makes it possible to reduce the alcohol content in beverages in an extremely gentle way while retaining the valuable aromas.

References dealcoholization

Dealcoholization of beer

Location: Turkmenistan

Batch size: 5.000l

Alcohol content: <0.1 vol%

Partially automated

Integrated CIP tank

Dealcoholization of wine-based beverages

Location: Germany

Batch size: 5.000l

Alcohol content: <0.5 vol%

Partially automated

Integrated CIP tank